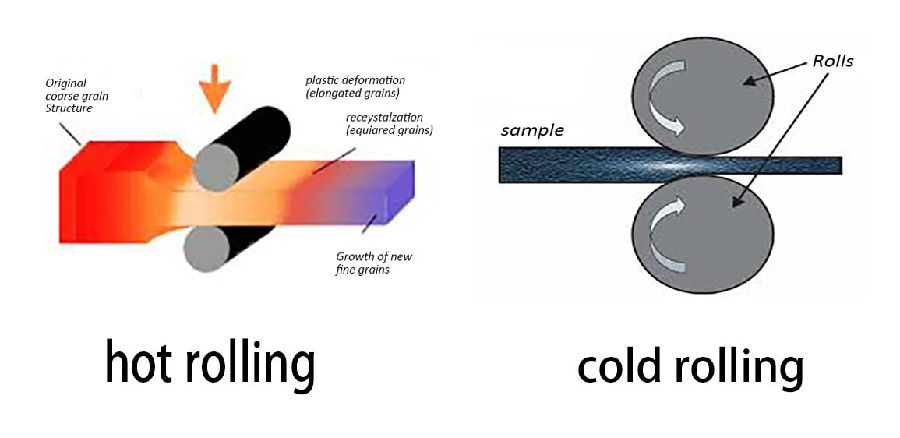

Bothcold rolled and hot rolled steelstart out as large steel slabs or billets cast from hot liquid metal. The billets are then heated, eventually reaching over 1700°F. At this high temperature, they are easily flattened into a long sheet using a set of rollers, ...

When you want to create astrip mill, it is very important to choose the right type of strip to produce.So your options should be careful.

First of all, the selection and judgment should be made based on the market situation. Is the market targ...

Hot rolled steel coil is made of slab (mainly continuous casting slab) as raw material, which is heated and then made into strip steel by ...

The first hot rolled coil production line is the 2800/1700 semi-continuoushot strip millof Angang Steel Company Limited. This production ...

Hot rolling can improve the processing performance of metal and alloy, that is, the coarse grain in casting state is broken, the crack is obviously healed, the casting defect is reduced or eliminated, the cast structure is changed i...

What is thehot rolled steel?As the name implies, “hot rolled steel” refers to the steel rolled by high temperature heating.The rolling process undergoes high temperatures of over 1,000°F, which is above the re-crystallization temperature for most steels...

The production process of cold rolled coil is slightly different according to the variety and specification of raw materials and products. The general process of cold rolled steel coil is introduced as follows.

1.Pickling.A continuous pickling...

Cold rolling of steel began in Germany in the mid-19th century, only 20--25mm wide cold rolled strip steel could be produced in that time.The 25 mm cold rolled strip mill was established in the United States in 1859, and a low carbon steel strip with a width of ...

The first continuous (tandem) rolling coil production line was born in US in 1925. This is the first hot continuous rolling coil mill in the world.From this production line, the hot rolled coil production technology has three phases. <...