Home > News& Media >> News

Blooming mill--(2)

DATE:8/18/2019 HIT:994 SOURCE: AUTHOR:

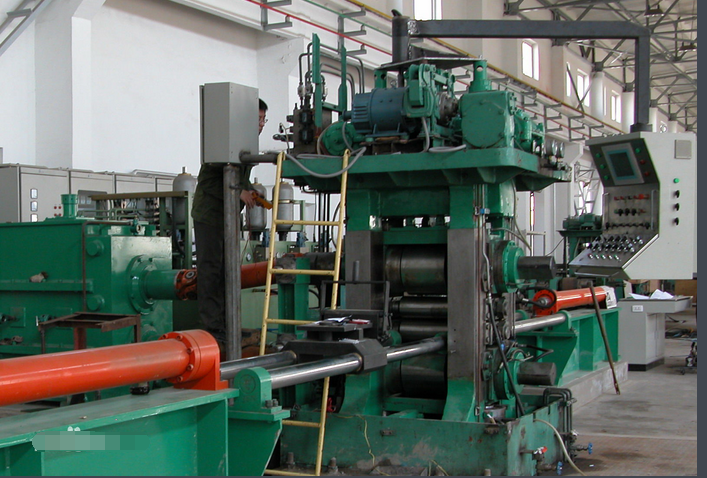

Three-roller blanking machine

The rolling mill has three rolls, the rolls do not need to be reversed, the mill construction cost is low, and the energy consumption is low. 70% of its operating power is used for deformation of steel ingots. Since the hole type is fixed, the product specification is small in flexibility and the product range is narrow. In addition, swinging platforms must be provided before and after the mill. The three-roller blanking machine is mainly used in small and medium-sized enterprises.

Billet continuous rolling mill

This type of rolling mill is a tandem arrangement of several two-roll mills in which the direction of rotation of the rolls is constant. Its billet and finished product have poor adaptability, but it can be used for high-efficiency rolling of small and medium-sized billets or thin slabs that require a large amount and a constant cross-sectional shape. The billet continuous rolling mill is generally arranged after the preliminary rolling mill, and the ingot is first rolled into a large billet and then enters the continuous rolling mill. For the continuous rolling mill with the horizontal roller and the vertical roller alternately, the steel bar does not need to be turned between the frames, so that the rough rolled blank can be accepted, and the surface crack of the steel slab caused by the occurrence of tensile stress caused by the steel turning is solved. Problems such as wear of the steel turning machine.