Hot rolling steel strip Line

DATE:8/8/2018 HIT:1672 SOURCE: AUTHOR:

Part 1 Production scale, raw materials and product specifications

1. Production scale: Annual production 0.8~1.2 million tons

2.Raw material:Continuous casting billet、slab strip

Blank thickness: 150~200mm

Blank width: 150~480mm

Blank length: 6~12m

Steel grade: carbon structural steel, high-quality carbon structural steel, stainless steel

3.Product specifications:

Thickness: 1.0~8.0mm

Width: 145~500mm

Steel roll weight: Max 5600kg

Outer diameter of steel roll: Max Φ1650mm

Inner diameter of steel roll: Φ500mm

Part 2 Process flow introduction

Part 3

Rolling line configuration and unit characteristics

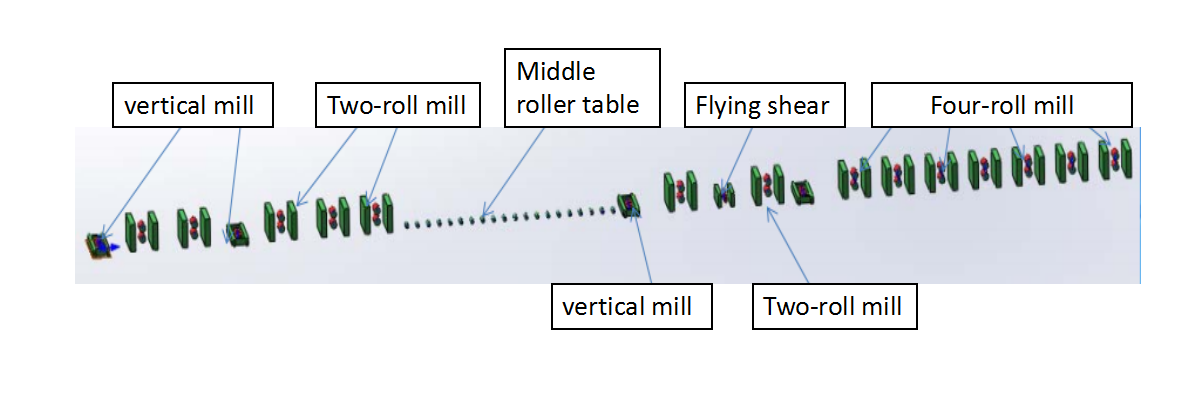

The hot rolling steel mill adopts a full continuous rolling arrangement, rough rolling and finishing strip rolling

A. The roughing unit is generally composed of two vertical rolls and five horizontal rolls (if forced wide-rolling, the arrangement is two vertical and six horizontal). There is no looper between the frame, using the micro tension to hot rolling. In order to ensure the width accuracy of the strip, the rough rolling stand is hydraulically pressed and realizes short stroke control of AWC+SSC head and tail width. The rolling method of rough rolling two-roll mill is hydraulic APC.

B. A heat preservation cover is arranged on the transmission line side between the roughing mill and the finishing mill. The heat preservation cover is used to reduce the heat loss of the intermediate blank, ensure the temperature of the intermediate blank entering the finishing train, and obtain a product with uniform mechanical properties.

C. A drum-type flying shear is arranged between the F1 and F2 of the finishing mill. It is used for optimized billet cutting and helping the finishing mill bite into the billet

D. The finishing mill is generally composed of two vertical rolls and nine horizontal rolls (suitable for rolling 1mm strip products), and electric loopers are arranged between the frames to ensure constant tension rolling; all rolling mills are hydraulically pressed. The rolling method of the last four flat rolling mills of the finishing mill is hydraulic AGC, which automatically controls the thickness, presses the pressure feedback and pressure signal in the system, and the magnetic displacement sensor is used for the closed loop control and digital display of the roll gap.

E. The roller adopts the four rows of short cylindrical roller to bear the rolling force. And the thrust bearings to support the axial force.

F. Rough mill and finishing mill use the DC motor to drive.

G. The main mill reducer of rough mill and finishing mill adopts hard tooth surface reducer, and the reducer bearing adopts SKF, FAG or Timken imported products.

H. The vertical mill is used to control the width of the strip. All the vertical mills are separate mills.

I. The roller of the full line and the furnace zone and rolling zone is lubricated by oil and gas.

J. The dust removal of the finishing mill is combined with water pressure and plastic burning board.

K. The roughing and finishing mills change rolls by hydraulic.

L. Both the roughing mill and the finishing mill are equipped with adjustable inlet and outlet guides.And the coarse and fine-rolling guides can be adjusted by full hydraulic and displacement sensor.

M. After the finishing mill, there are advanced measuring instruments such as thickness gauges and width gauges, and the width and thickness of the strip can be monitored in real time.

N. A simple ultra-quick cooling device is added in tripledistrict to reduce the maximum temperature of the strip by about 150℃, effectively reducing the scale and improving the microstructure of the product.

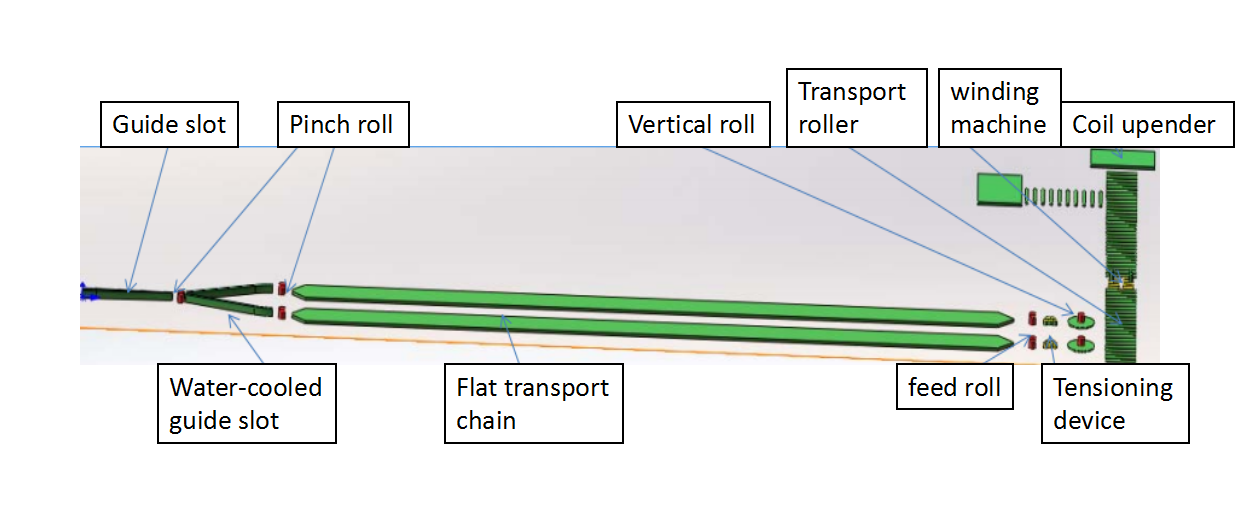

O. Pinch rollers in triple districtbead weld hard alloy on the surface.

P. Adopt vertical winder, and winder is reduced-core type.

PART4

Main equipment structure parameters

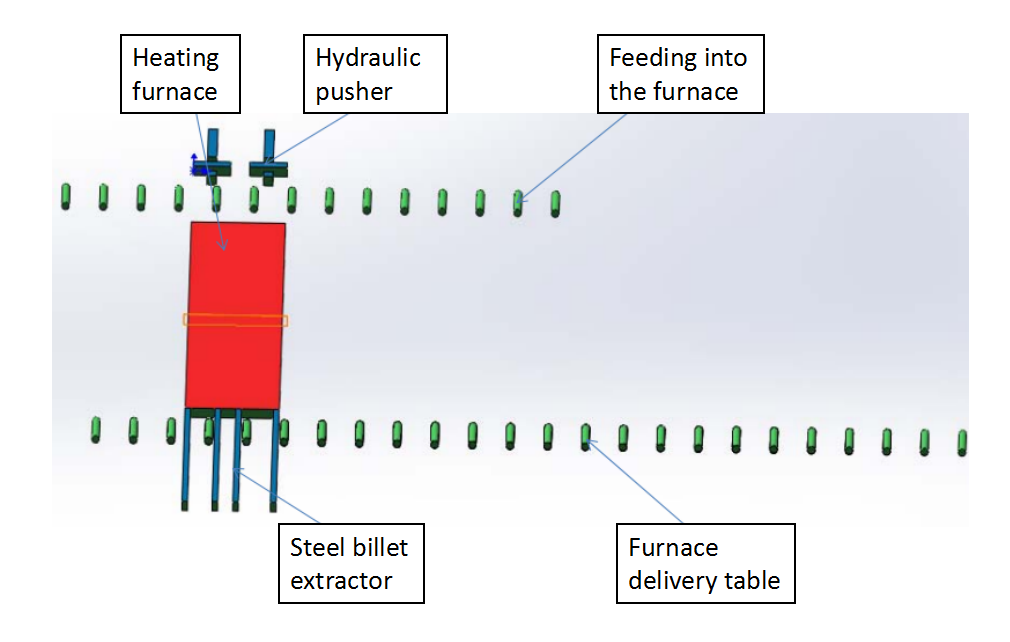

1. Furnace area

2. Rolling area

3. Collecting area

PREV: Hot rolling steel strip Line

NEXT: ...