Hot Rolling Steel Bar Line

DATE:9/5/2018 HIT:1271 SOURCE: AUTHOR:

Part 1 Production scale, raw materials and product specifications

1. Production scale: annual production of 0.3-1 million tons

2. Material: using the continuous casting billet produced in the steel making workshop as raw material

Blank standard: 100% continuous casting billet

Blank thickness: 150mm

Blank width: 150mm

Blank length: 12000mm

3. Production specifications

Production: Φ12mm~Φ40mm screw steel, Φ16mm~Φ40mm round bar steel

Steel grade: High quality carbon steel; Carbon steel; Low-alloy steel

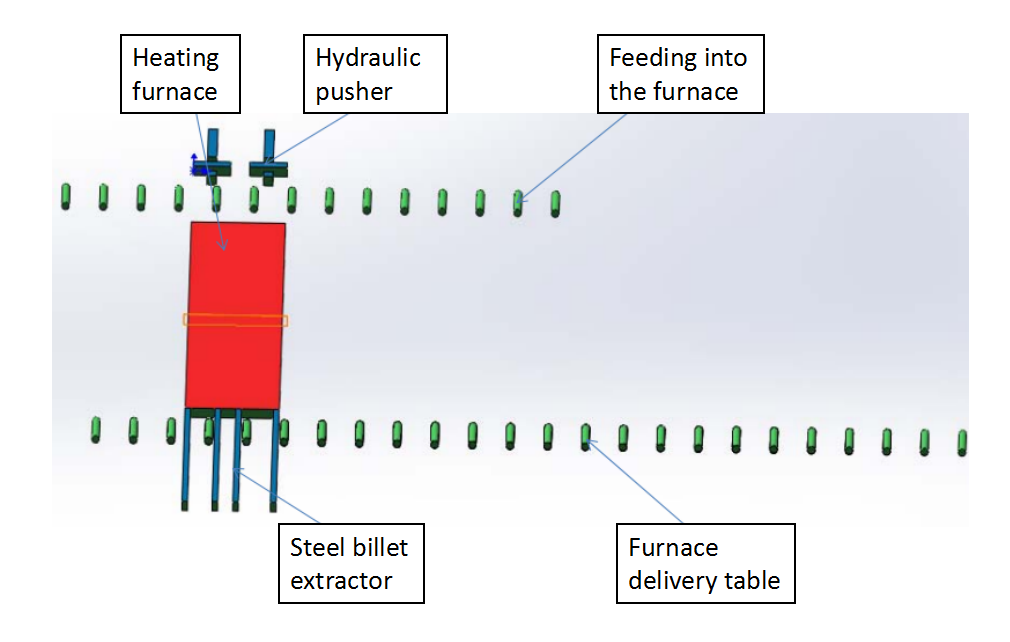

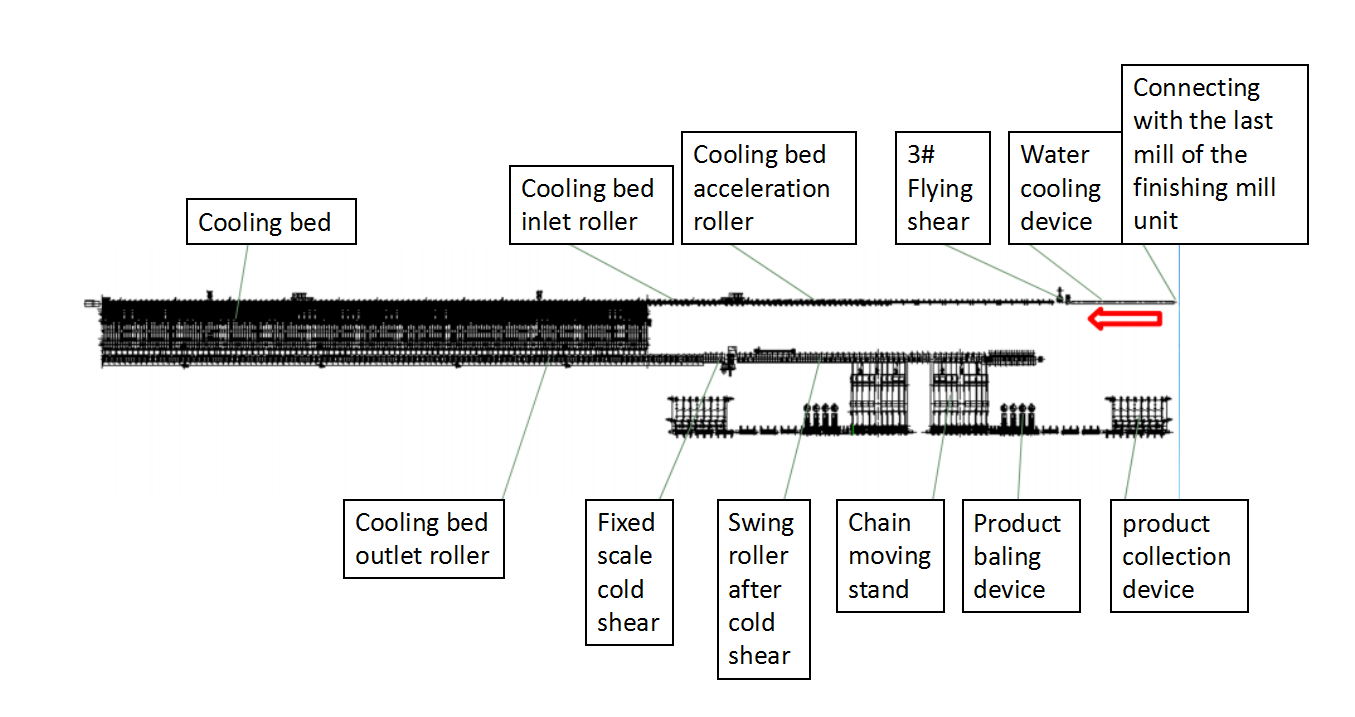

Part 2 Processflow introduction

Part 3 Units equipment level and its characteristics

The main technology of hot continuous rolled bar production line equipment:

l Full continuous rolled, less accidents, easy operation and maintenance;

l The automation control system is perfect to ensure the high output, high efficiency, low cost and high quality of the rolling mill.

l The rolled speed is high and the mill productivity is high;

l The rolled mill adopts POMINI short-stress line rolled mill to ensure high-speed rolled and split rolled;

l The unit is arranged alternately to realize the torsional rolled, the coarse and medium rolled micro tension rolled, and the finishing rolled without tension rolled, which can ensure the high precision of the product;

l Finishing mill is equipped with water-cooling device before and after, which can produce Grade III threaded steel bars;

l The rolled mill adopts a hydraulic traverse device, which is convenient for quick replacement of the roll hole type;

l The rolled mill unit adopts the integral rack quick change device, which can greatly improve the production operation time;

The rack-type cooling bed is used, the rolled parts are cooled evenly, and the rolled parts have straightening effect;

PART 4 Main equipment structure parameters

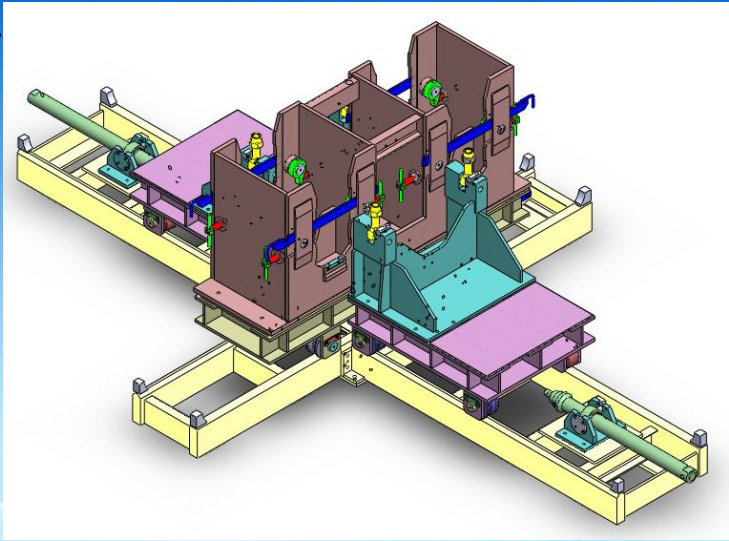

1. Furnace zone equipment

2. Rolled zone equipment

3. Collection area equipment

4. Offline equipment