Home > News& Media >> News

Discuss the cause of the broken roll

DATE:7/20/2020 HIT:1340 SOURCE: AUTHOR:

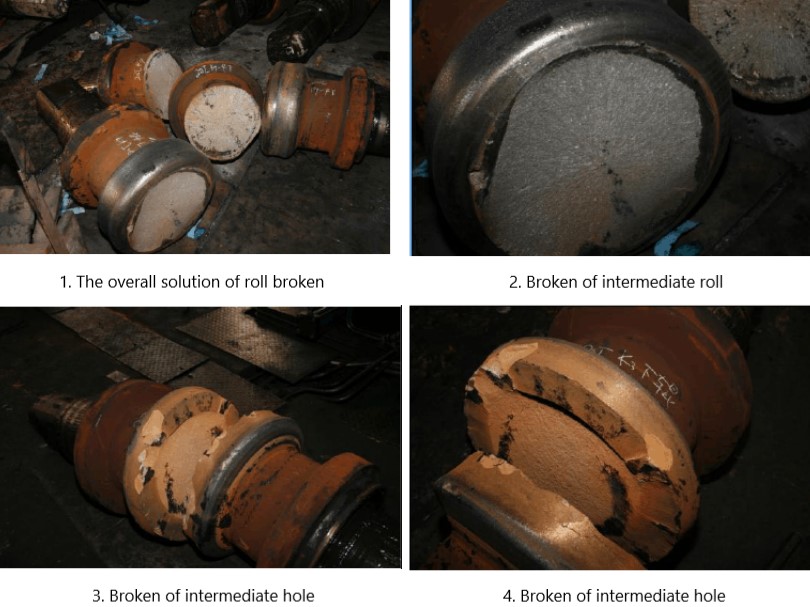

Roll broken is a destructive accident that often occurs in rolls

1. The reason for the roll itself (material, manufacturing, etc.);

2. External factors (use conditions, such as rolling force, rolling torque overload, etc.).

Due to the roll material and manufacturing defects, the defects such as trachoma, slag inclusion, and cracks can generally be detected at the fracture; the rolling force, rolling force, rolling force, rolling force, rolling force, rolling force, rolling force, rolling, etc. The break caused by the brake torque overload should be avoided as far as possible.

|

Broken roll form |

Cause Analysis |

|

Central fracture of steel plate roll |

The flatness of the fracture is due to excessive rolling pressure and rapid cold rolls; there is a circle of oxidation marks on the fracture, which is caused by the development of ring cracks. |

|

The roll with a hole is broken at the bottom of the groove |

It often occurs in the later stage of the use of the old roll. If such a phenomenon occurs in the new roll, the process conditions such as rolling pressure, steel temperature, reduction, and the material of the roll should be checked |

|

Root break of roll neck |

The transition fillet radius r at the root of the roll neck is too small, causing stress concentration; too high bearing temperature may also cause roll neck fracture |

|

Twisted roll neck |

The fracture is 45°, the torque is too large, the transmission end is prone to happen |

|

Roll head twisted off |

It often breaks from the root of the roll head. When cold rolling thin strip steel, the roll pressure is too high. At this time, the torque can be greater than the rolling torque, and the roll head may be broken when the rolling mill is started. |