Hot rolling wire line

DATE:8/8/2018 HIT:1183 SOURCE: AUTHOR:

Part 1

Production scale, raw materials and product specifications

1. Workshop production scale:

Rated working time of the year 6500 hours, the annual production tells 600,000 tons of non-twisted hot rolling wire rod products.

2.Raw materials:

The continuous casting billet produced by the steel making workshop is used as raw material.

Blank specification: 150*150*6000-12000mm, 165*165*6000-12000mm

3. Product:

High speed twistless hot rolling wire rod

Product specifications: Φ5.5-16mm glossy wire rod

Φ6.0-16 threaded wire rod

Coil inner diameter:Φ850mm

Coil outer diameter: Φ1250mm

Production of steel grades: ordinary carbon steel, high quality carbon structural steel, low alloy steel, welded steel (including new material welded steel), cold heading steel, bearing steel and so on.

Delivery status: delivery in rolls, 4 traps.

Coil parameters: inner diameter Φ850mm, outer diameterΦ1250mm, coil weight~2000kg

Product accuracy: ±0.15mm

Ellipticity is not greater than 80% of the total deviation

Executive standard: ZBH44001-88(B); ZBH44002-88; GB701+1997; YB4027-91; GB/4354-1994;

GB/T3429-2002; GB/T6478-2001; GB/T14981-1994(B); YB/T038-93 and so on.

Part 2

Processflow introduction

Process flow: The entire production line is arranged in an elevated position. The main unit is arranged on a platform higher than 5 meters.

Continuous casting billet hot feeding - heating furnace heating - high pressure water descaling - roughing mill rolling -1# flying shear head, tail cutting - medium rolling mill rolling - 2# flying shear head, tail cutting - pre Finishing mill rolling-water cooling-3# flying shear head-finishing mill rolling-water cooling-spinning machine spinning into coils-winding cooling-collection-cutting head-coil shipping line transportation- Sampling, inspection - compaction and bundling - weighing, listing - unloading - lifting and storage

Part 3

Main design features and equipment level of the production line

l High-pressure water descaling technology before rolling to improve the surface quality of the wire;

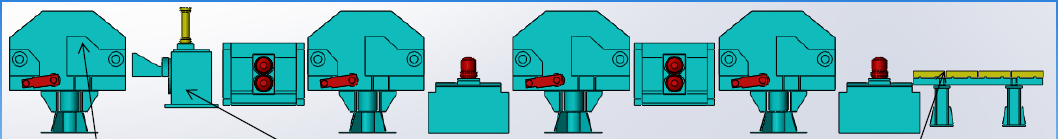

l The full-line rolling mill adopts a flat and alternate continuous arrangement scheme, and the rolling stock is not twisted, thereby reducing accidents and quality problems caused by twisting;

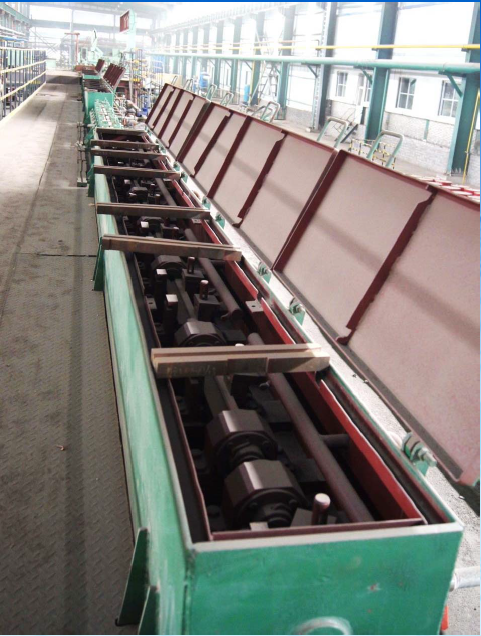

l The coarse and medium-sized rolling mill adopts a new type of short-stress rolling mill, which has been gradually improved and is now reaching the advanced level in the industry.

l The finishing mill adopts the Morgan type V generation top 45 degree rolling mill, which proves to have high reliability through production practice. The mill has a maximum design speed of 105m/s and a guaranteed speed of 90m/s.

l The hole type system adopts elliptical-round hole type, and the pre-finishing and finishing rolling mill adopts rolling guide to ensure stable rolling and reduce scratches.

l Main design features and equipment level of the production line

l High-pressure water descaling technology before rolling to improve the surface quality of the wire;

l The full-line rolling mill adopts a flat and alternate continuous arrangement scheme, and the rolling stock is not twisted, thereby reducing accidents and quality problems caused by twisting;

l The coarse and medium-sized rolling mill adopts a new type of short-stress rolling mill, which has been gradually improved and is now reaching the advanced level in the industry.

l The finishing mill adopts the Morgan type V generation top 45 degree rolling mill, which proves to have high reliability through production practice. The mill has a maximum design speed of 105m/s and a guaranteed speed of 90m/s.

l The hole type system adopts elliptical-round hole type, and the pre-finishing and finishing rolling mill adopts rolling guide to ensure stable rolling and reduce scratches.

PART4

Main equipment structure parameters

1. Furnace area

2. Rough and medium rolling area

3. Pre - finish rolling and finish rolling

4. Cooling control - water piercing and coil cooling lines

5. collecting area

PREV: ...

NEXT: ...