Home > Products & Services >> Product >> Pipe Mill >> ERW Pipe Mill

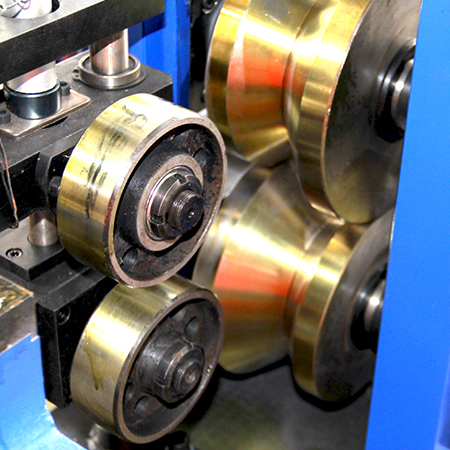

High frequency 20*406.4 mm FFX 16" Steel strip ERW pipe production mill

DATE:6/14/2019 HIT:892 SOURCE: AUTHOR:

The High-frequency-Steel-strip-ERW-pipe-production-mill is used to process a strip coil with a thickness of δ=5.5-20mm and a plate width B=520-1350mm into a straight seam welded pipe with a diameter of φ168.3~φ406.4mm, such as opening, leveling, forming and welding. It is equipped with medium frequency annealing, ultrasonic flaw detection, trimming flat head and hydraulic test, and can produce straight seam welded pipes that meet API 5L, API 5CT, GB/T 3091, ASTM A513, EN 10219 and other related standards. The electronic control system adopts Siemens PLC automatic control system, DC speed control system and digital display system. Simple operation, convenient maintenance and high reliability.

Technical parameter of the unit

|

Steel coil O.D. |

1200-2000mm |

|

Steel coil I.D. |

760mm |

|

Steel coil width |

520-1350mm |

|

Material |

Line pipe: X42-X80 |

|

Steel plate thickness |

5.5-20mm |

|

Steel coil weight |

Max. 30tons |

|

Product standard |

API 5L ,API 5CT ,GB/T 3091, ASTM A513 ,EN 10219 |

|

Pipe diameter |

65/8"~16"(Φ168.3~Φ406.4mm) |

|

Pipe thickness |

5.5-20mm |

|

Pipe length |

6-16m |

|

Length tolerance |

0-6mm |

|

Max. testing pressure |

60Mpa |

|

Welding mothed |

High frequency induction (contact) heating extrusion forming |

|

High frequency equipment power |

1200KW(solid state) |

|

Frequency |

400-450KHz |

|

Welding speed |

10-30m/min |

|

Weld Annealing |

Medium frequency induction heating |

|

IF equipment power |

4*600KW |

|

Elevation |

+1200mm |

|

Output |

150000-250000tons/year |